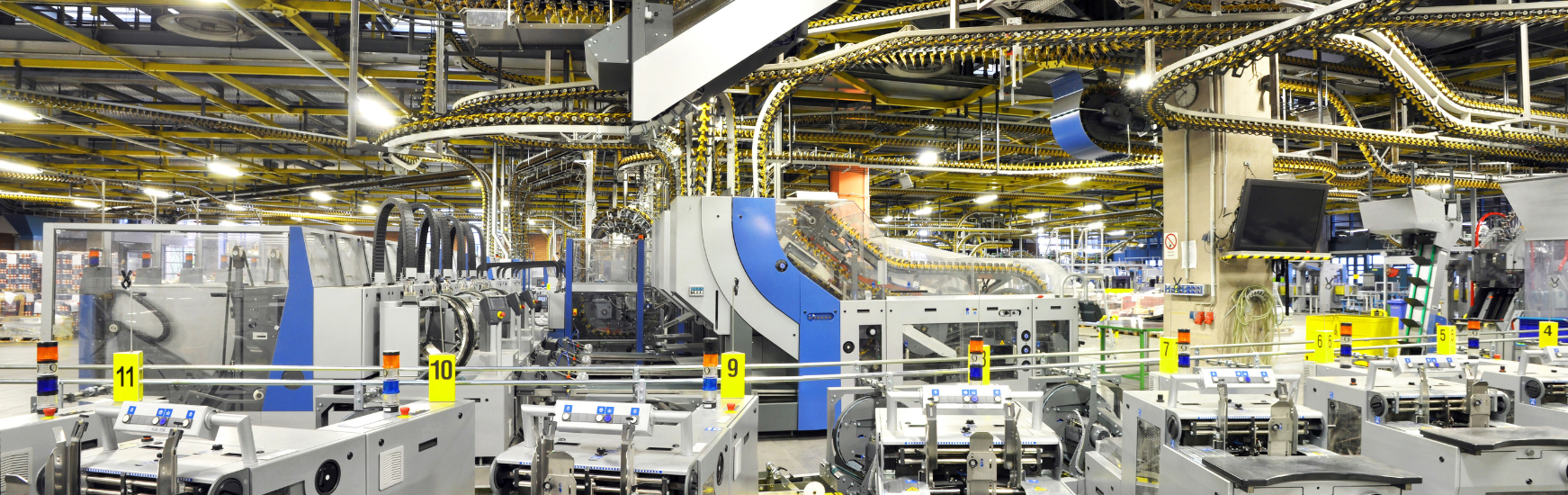

How is edge computing changing manufacturing and fulfillment?

The manufacturing sector is undergoing a considerable transformation, with automation taking the driver’s seat. Manufacturing units with IoT, AI, Robotics, and smart sensors are creating a buzz in the industry, and if you do not want to be left out, embracing these technologies is crucial. Edge computing brings data storage and processing close to the network edge facilitating quicker access. It is predicted that by 2025 there will be 21.5 billion connected IoT devices. The interconnecting network will lead to intelligent manufacturing.

Cloud strategy and edge strategy go hand in hand. Edge computing improves efficiency by connecting operational data and other assets to complement cloud computing and IoT. It addresses the manufacturing operations’ latency, security, and reliability while facilitating remote connectivity. Edge computing helps to monitor all the machinery across the factory floor with the help of intelligent sensors and IoT. The use of predictive maintenance tools helps to detect and fix potential problems. Real-time tracking is another crucial tool to enhance visibility across the supply chain.

The primary role of edge computing is to move the manufacturing process close to the data source. Local infrastructure will process the data without relying on centralized data centres.

Benefits of Edge Computing in Industry 4.0

1. Low latency can be reduced drastically with the edge. When equipment malfunctions, the signal must be transmitted immediately; any delay could cost dearly. The delay could also lead to injury and more damaged parts. Low latency is vital for an interconnected system to function as designed. When industrial computing occurs at the source, the issues would be nil.

2. Smart factories must increase cybersecurity to end vulnerabilities like hacking and Denial of Service attacks. Factories can be protected from network breakdown if the processing and storage functions are routed through the edge. The data is at less risk when it is closer to the data source. Manufacturing units have been most vulnerable to cyberattacks in the recent past. Robust cybersecurity is the key and edge can offer it.

3. The new industrial revolution is sparked by Big Data. To analyze data of this amount, there is a requirement for huge storage, computing power, and bandwidth. Edge computing can address these concerns. Firstly, data is processed near the source, making the transaction faster. Secondly, data points in the smart factory store and process information, giving outsiders no scope to access the data.

4. Interoperability is a significant concern and is a hurdle to expansion. Now with computing functions at the edge, the requirement for the universal standard is eliminated. The devices convert signals, and they work with a host of systems. The edge acts as a link between data and operation, resulting in a smart factory.

5. When there is extensive data, substantial storage is needed. While using traditional data is inconvenient, cloud service is an expensive proposition. Manufacturing units have to draw a line between the two, and edge is the ideal ground to cut down on storage costs. Edge storage sends only relevant data to the cloud. The edge analysis data locally before sending it to the cloud. It reduces the pressure on cloud analytics and saves on storage costs. With edge, each machine will handle only its data resulting in an organized and inexpensive storage solution.

For the manufacturing sector to reach its full potential, it has to embrace edge technology. Though the transformation does not happen by swinging the magician’s wand, it takes time, but when it happens, it can be the key to the future of Industry 4.0

SMOAD for manufacturing

SMOAD gives the advantage of performing multiple manufacturing and fulfilment functions at the machine level. Edge routers provide last-mile connectivity to your manufacturing units. The edge routers offer internet connectivity to receive inbound traffic by securing IP traffic from the server or other routers. The SMOAD edge router acts as a gateway to branch routers. Starting from the factory floor to fulfillment centers, the edge reigns supreme.